Model Scanning For Upcoming Fashion Show

I am closely involved in organizing the upcoming fashion show at the Inside 3D printing conference in April. I’ve already cast a team of models who are being scanned to create custom 3D printed outfits. Here, we see Mel and Shelly Lynn being scanned over at Body Labs. I am fortunate to be working with some very lovely and talented ladies on this project.

The scanner Body Labs uses at their office is an 0ff-the-shelf laser scanning booth that was originally designed to measure soldiers for Army uniforms, I believe. While it is not extremely detailed, it is very fast, scanning top-to-bottom in just a few seconds. Most models were scanned 10-20 times, but Mel and I spent a good couple of hours and kept having ideas.. all in all we created more than 100 scans – a marathon session for sure.

All of these scans have been added to the Body Labs database and are used to refine their algorithm to create more accurate body shape and pose estimations. Obviously this technology is great for customizing designs, but a more short-term goal is for us all to be able to go shopping online with our digital profile and be sure that everything we buy will fit perfectly.

All of these scans have been added to the Body Labs database and are used to refine their algorithm to create more accurate body shape and pose estimations. Obviously this technology is great for customizing designs, but a more short-term goal is for us all to be able to go shopping online with our digital profile and be sure that everything we buy will fit perfectly.

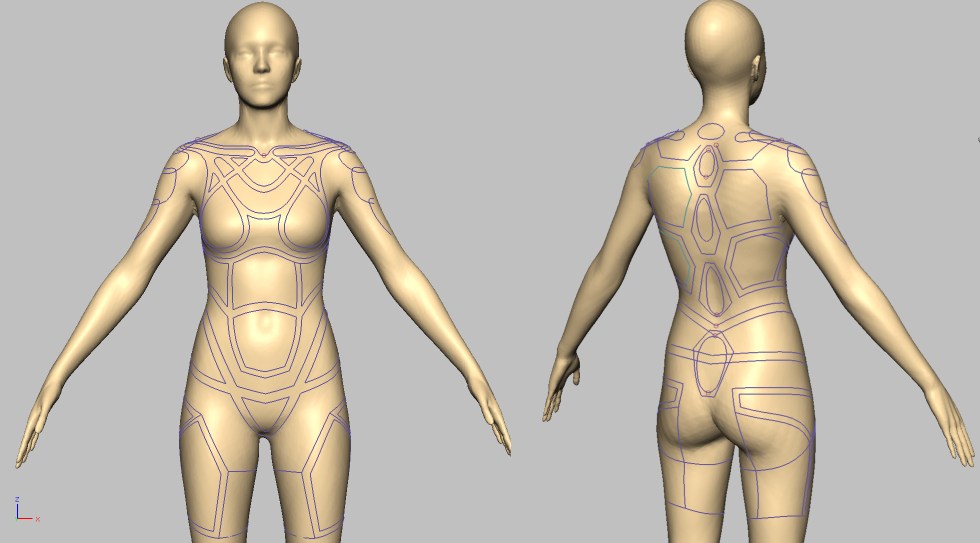

Another unique capability brought by the pose estimation algorithm is that it enables a point-to-point correspondence between subjects. That means that measurements can be compared between individuals or the same individual in different poses. By adapting a generic mesh to the shape and pose of a scan subject, the mesh can be adjusted to match, thus creating a digital avatar that can be posed and animated. By applying this process using the same input mesh, the output avatar is topologically consistent between individuals. By having the same structure, the avatars – or designs created from them – can be morphed and blended. Below is a demonstration; a continuous morph between all models in the entire team.

This body-morphing ability was later used to good effect during the show. Since some parts of the lineup were not predictable (in terms of which model would wear which piece at one time), it was desirable to create generic accessories with a high likelihood of a good fit. This was done by population averaging of our team. Runway models are not average compared to the US population – they tend be tall and slender. By averaging them together I created a virtual model (dubbed “Ave”), which I used to create general-fit designs.

I later gave a presentation explaining this process, as well as cranium averaging used for the Ultracortex project, as part of the proceedings at the Rapid 3D technology conference. The presentation was called “Reverse Engineering The Body For Product Design”.