Digital Apparel Defined

The field of development known as “Wearable Technology” is suffering from a labeling issue. The technologies referred to are usually specific products that are not just wearable, but must be worn. They are designed to function in the context of the body. What constitutes “technology” is also fairly vague, since the phrase refers not just to electronic gadgets, but all sorts of innovations like specialized textiles, materials with engineered properties, prosthetic devices, or sensors and displays, in addition to “smart” products that have some level of computational ability and often communicate with other technology. I’ve broken down Wearable Tech into categories to provide an organizational framework for my work in custom-fit 3D printed products before, such as in my presentation at the 2013 Rapid convention (PDF transcript, video). Rather define these things for the audience every time we mention or discuss this family of technologies, it would be much easier to find relevant sub-sets that can be grouped under a single label. The phrase I use to describe my area of work is “Digital Apparel”. Of the many word choices available, “apparel” from the Old French “apareillier”, meaning “to make fit”, is an ideal choice to pair with the digital and technological processes that distinguishes the subject.

Digital Apparel includes a collection of information that defines a product worn on the body. The definition includes a three dimensional geometric definition that can be adjusted for different individuals. Customization can be defined through simple sizing variations or through parametric and generative components. In addition to geometry, an Item of Digital Apparel must be designed with specific processes and materials in mind, and specific intent in terms of function and aesthetics. It may also include transformational, iterative, or reactive geometries which are currently being covered by the oddly chosen phrase “4D [printing]”. The final criterion is that the product is made primarily through industrial processes.

The best way to address the many possible interpretations and misinterpretations is as question-and-answer. So here we go:

Is Digital Apparel clothing made on the computer?

It is the definition of the “clothing” while it is still on the computer. After production it is currently called either clothing (apparel), or wearable technology.

Is Digital Apparel referring to designs for 3D printed clothing and wearable technology?

It can, if the definition of those things is complete. Most advanced commercial wearable technology is produced along with PLM (Product Lifecycle Management) systems (Such as the ones from Siemens that work with their NX CAD software), and so contains the required information to meet the definition. 3D printed clothing is usually just a static 3D model, but if all the requirements are completed, such as a selection of sizes, and design for a specific material and 3D printing process, the design will meet the definition. As a simple example, a 3D design for something like shoes or a hat in a selection of sizes (while maintaining all key dimensions and features), designed with appropriate tolerances for FDM printing in PLA on a home printer, would meet the definition.

What about simple items like jewelry?

While they could be available in sizes and have material and process specified, the spirit of the definition is geared toward enabling discussion of pieces that distinguished by having larger size or complex shape that necessitates accurate size and shape, or specific functional requirements that require some knowledge by the designer about the context on the body. It also meant to refer to objects that are not purely decorative (have some technology component), so this usage would not be appropriate.

Smart watches and necklaces have tech, are they digital apparel?

Wearable technology, while an awkward phrase, is most pointedly referring to these gadgets, so that is the more appropriate phrase to use. If you wouldn’t call the resulting product “apparel”, you probably should not call the design an example of Digital Apparel. There is not a hard line between them however, particularly because the digital design and customization allows many more variations of form that don’t fall cleanly into categories like “Shirt” and “Pants”. I do think the Digital Apparel definition should be extended to forms that do not entirely envelope the torso, and so in some sense could be called “Accessories”, though that term is broad enough that it also refers to very small items. The phrases are not exclusive, but refer to different things. The core features of Digital Apparel are the customization and production information aspects that accompany the design intent.

Are there examples of of on the market already?

Yes. I offer 3D printed accessories and garments that are customized based on body scans and manufactured via 3D printing. There is software on the market such as Marvelous Designer that can be used to create a 3D dimensional design and output to 2D patterns for production. These patterns are cut through CNC, but are still assembled by hand, which falls short of being produced “by an industrial process”. However, there still can be no hard line, since even 3D printed designs are partially processed by hand. The important characteristics that helps distinguish Digital Apparel from traditional manufacture are the production specifications; which material, how they are cut and assembled- all of that information is needed for a complete Digital Apparel design. Doing something like downloading a 2D pattern, manually cutting the cloth and assembling it does not meet this definition. Aside from the fact the re-sizing would require experienced knowledge of the craft, there are numerous decisions made by the fabricator that would produce variability from one producer to the next. There is currently a fully automated robotic assembly project sponsored by DARPA for producing military uniforms that are custom fit for each individual. This would be an example of a Digital Apparel system. There are also several 3D weaving projects and 3D printing projects (such as the work I do with ThreeForm) that are carefully designed to be produced as repeatable, variable products. They are rare and expensive, not yet in mass produced form, but I would count them. One can also find examples of Mass-customization online, such as systems from Nike that create customized designs through a web interface. As final assembly of these products becomes more automated, the results become more pure examples of Digital Apparel.

If I extract an outfit from a video game for example, size it to myself, and 3D print it, is it Digital Apparel?

No. The model would have to be thickened and heavily modified in many ways to make it print and function. All of that input requires planning and design to match with particular materials, processes, and functionality of the result. It could be possible for a designer to formalize this information and creative a derivative work which is Digital Apparel, from just about any geometry they choose, as long as it meets all the criteria.

Is Digital Apparel a format?

No. There are a number of systems available for managing product information, and many of them pass on production information to the manufacturer. Again, this is not a black-and-white distinction, since for example a whole line of products might be designed to print in nylon12 using the common selective laser sintering 3D printing process. The actual process and material selection is inherent in the product and planned by the designer, but the producer may only offer that one choice, so there is no need to specify in any digital file. It should suffice that all the implications of the production process were planned by the designer to achieve a specific result, and as long as the design is “fit for the environment” that it is released into, it will successfully meets the definition.

How would anyone know what formats and software to use, and how to communicate the correct information?

Right now, all that is required is for the files to be compatible with the equipment, and all relevant information to be communicated along with the file, whether grouped into an archive and sent via FTP, transferred via a PLM system, or simply communicated along with an email attachment. Standards have not yet been created, and all of these things are adapted to the context, which is why this is not a consumer-level activity at this time.

What are the next steps? When do consumers get to buy Digital Apparel?

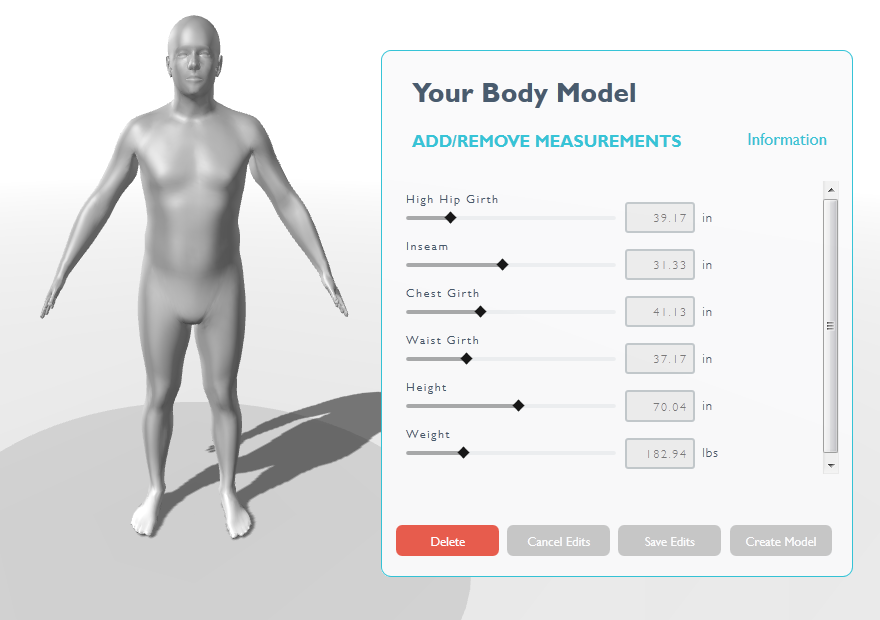

They can right now. In addition to hiring a specialist to create flexible digital designs, companies are creating software to simplify various parts of the process. The New York company Body Labs has a system that makes it simpler for companies to get input from customers to do customization in a less ‘couture’ arrangement. Ultimately we will all have digital profiles that are compatible with online shopping systems that will place orders and begin to manufacture customized garments – often with integrated technology components – with very little effort and relatively low cost.

The tension between the selective forces comes from the fact that those systems work best when many people wants the same thing, and customization works best when the customer wants a different thing from what is being commonly offered. I feel there will always be a spectrum of solutions, from the mass-produced simple functionality like a custom-fit piece of clothing with a simple sensor or indicator, to completely bespoke “wearable systems” that may enable complicated sets of interacting functionality, such as treatment for health issues or enhanced capabilities. At the extreme end of this development one might have most of their biological and functional needs covered, as in examples where a scientist might explore a remote area or even another planet.

All of these products that interact with the body must meet certain requirements to begin to evolve toward these final forms. Leaving out any specifications means work must be repeated for each iteration, and much of what was learned might be lost. It is by formalizing communication and design technique that standards will emerge to push forward development of both wearable technologies and Digital Apparel.